PRODUCTS

CONTACT US

Fast Delivery

Sufficient Inventory

Good Service

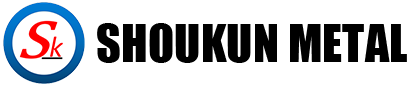

Hot-dip galvanized I-steel is also called hot-dip galvanized I-steel or hot-dip galvanized I-steel. It is to immerse the I-beam after derusting into molten zinc at about 500 ℃ to attach a zinc layer to the surface of the I-beam, thus achieving the purpose of anti-corrosion. It is suitable for strong corrosive environments such as various strong acids and alkali fogs.

Stainless Steel Unequal Angle Steel

Stainless steel angle steel is mainly divided into two types: equilateral stainless steel angle steel and unequal stainless steel angle steel, of which unequal stainless steel angle steel can be divided into unequal equal thickness and unequal thickness. The section height of unequal stainless steel angle steel is calculated by the long side width of unequal stainless steel angle steel.

Carbon Steel Unequal Angle Steel

Unequal angle steel is widely used in various metal structures, bridges, machinery manufacturing and shipbuilding, various building structures and engineering structures, such as beams, bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouses.

Channel steel is a long strip of steel with a groove-shaped section, which is a carbon structural steel for construction and machinery. It is a section steel with a complex section, and its section shape is groove-shaped. Channel steel is mainly used for building structure, curtain wall engineering, mechanical equipment and vehicle manufacturing.

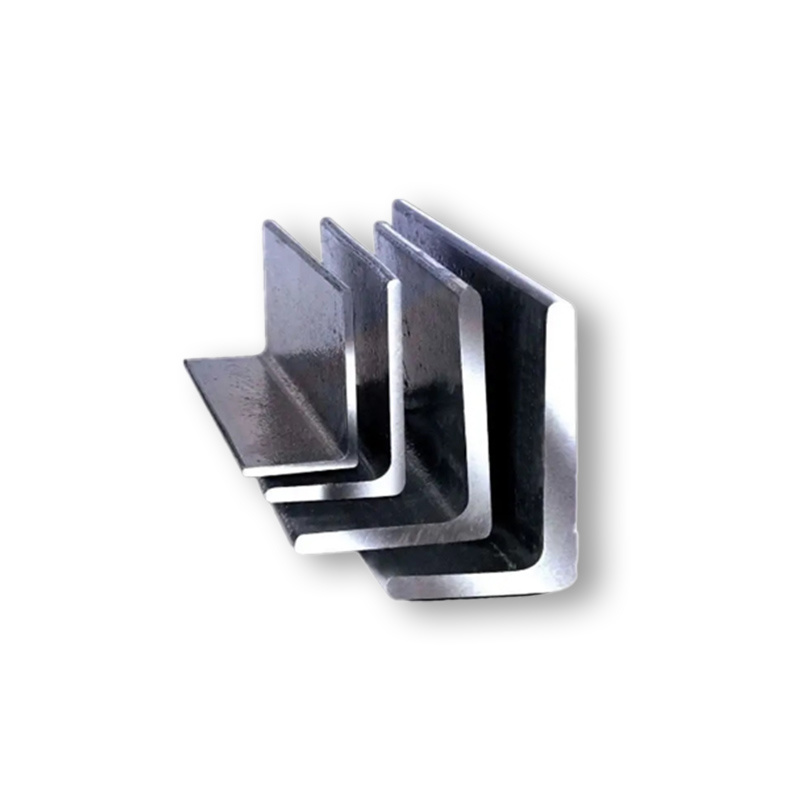

I-beam is mainly divided into ordinary I-beam, light I-beam and low alloy light I-beam. Ordinary I-beam and light I-beam flanges are thick on the web plate and thin on the outside. Ordinary I-beam, light I-beam, because the cross-sectional dimensions are relatively high, narrow, so the section of the two main sleeve moment of inertia difference is large, which makes it in the scope of application has a great limitation. The use of I-beam shall be selected according to the requirements of the design drawings.